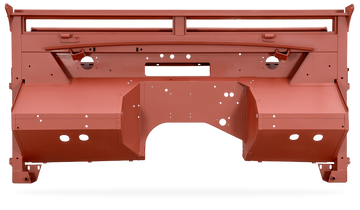

We Make Bespoke Bulkheads For Classic Land Rovers

Are you finding it difficult to source an identical bulkhead for your Land Rover Series model? We specialise in manufacturing exact replicas based on your vehicles production date.

Did you know there are 24 different variants just for the Series 2/2a models alone

Choose Your Land-Rover Model

Pegasus Finest Detailing

Adds Value, Most Cost Effective, Increase Expected Life Span, Saves Time

Restoring a classic Land-Rover is not just a hobby, it's an investment in your personal satisfaction, pride and joy. It's also a way to connect with history and culture, and create a sense of community among us.

It Started With a Simple Idea And Our Mission Remains The Same

To create high quality and original specification bulkheads that we wanted ourselves.

Long before fitting "new bulkheads" became a trend, Pegasus were devoted to reverse-engineering very precise drawings to replicate Rover's original specifications, using a three-dimensional CAD system. Each bulkhead part is skillfully fabricated and assembled using the same techniques as the welders back in the 1950s; helping to keep our rich history in the automotive sector alive as well as keeping your Land-Rover's true identity.